Motorola Leak Tester

Leakage Tester for Industrial Protection Compliance Testing

"Leakage Tester For Water Immersion", what does it mean?

When Motorola, the leader in walkie-talkie technology, need to automate their walkie-talkie leak testing process for water immersion, they look none other than Luvotech for the complete end-to-end solution.

We have developed the standard testing equipment that could perform the NON DESTRUCTIVE TEST for the IPX7. This has helped to ensure high product quality and low cost of quality (appraisal/testing cost).

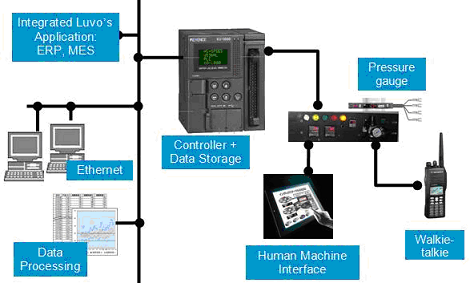

Our customized leak tester incorporates latest process and data automation technology that brings along itself proven advantage in productivity, efficiency, accuracy and traceability.

Process Automation: our controller-based solution enables automated data acquisition of vacuum sensor’s readings as well as driving the solenoid valve. Users’ configurable testing time and pressure settings allows changes per users’ testing spec. Our powerful Human Machine Interface ensure error free lot set-up process by the operators.

Data Automation: Microsoft .Net platform links seamlessly the controllers and server thus enabling real time testing information in production remotely accessible from engineer’s cubicle. Ethernet connectivity also makes trace-ability possible which in turn ensure no double testing on the same device/ full loop disposal of pass/fail device with respect to previous or next testing process for the device.

Other product that is usually tested to IPX7 are Marine rated GPS equipment or Fire Brigade communication equipment.

[Top]

[Top]

| |

Description |

Test |

| IP0_ | Non-protected | No test required. |

| IP1_ | Protected against solid foreign objects of 50 mm diameter and greater | The full diameter of a rigid sphere 50 mm in diameter must not pass through any opening at a test force of 50 N. |

| IP2_ | Protected against solid foreign objects of 12.5 mm diameter and greater | The full diameter of a rigid sphere 12.5 mm in diameter must not pass through any opening at a test force of 30 N. |

| IP3_ | Protected against solid foreign objects of 2.5 mm diameter and greater | A rigid steel rod 2.5 mm in diameter must not pass through any opening at a test force of 3 N. |

| IP4_ | Protected against solid foreign objects of 1.0 mm diameter and greater | A rigid steel wire 1 mm in diameter must not pass through any opening at a test force of 1 N. |

| IP5_ | Dust-protected | The test specimen is supported inside a specified dust chamber where talcum powder, able to pass through a square-meshed sieve with wire diameter 50 mm and width between wires 75 mm, is kept in suspension. |

| IP6_ | Dust-tight | All enclosures are tested as category 1, as specified above for IP5_. The protection is satisfactory if no deposit of dust is observable inside the enclosure at the end of the test. |

[Top]

The second character of the IP Code indicates the degree of protection against the ingress of water with harmful effects. Second character definitions are as follows:

| |

Description |

Test |

| IP_0 | Non protected, No special protection | No test required. |

| IP_1 | Protected against falling water Equivalent to 3-5mm rainfall per minute for a duration of 10 minutes. Unit is placed in its normal operating position. | Water is dripped onto the enclosure from a “drip box” having spouts spaced on a 20 mm square pattern, at a “rainfall” rate of 1 mm/min. The enclosure is placed in its normal operating position under the drip box. Test time = 10 min. |

| IP_2 | Protected against falling water when tilted up to 15 degrees. Same as (1) above but unit is tested in 4 fixed positions - tilted 15 degree in each direction from normal operating position. | Water is dripped onto the enclosure from a “drip box” having spouts spaced on a 20 mm square pattern, at a “rainfall” rate of 3 mm/min. The enclosure is from its normal operating position, under placed in 4 fixed positions tilted 15 the drip box. Test time = 2.5 min. for each position of tilt. |

| IP_3 | Protected against spraying water, Water spraying up to 60 degrees from vertical at 10 liters/min at a gage pressure of 80-100kN/m2 for 5 min. | from Water is sprayed onto all sides of the enclosure over an arc of 60 vertical, using an oscillating tube device with spray holes 50 mm apart (or a hand-held nozzle for larger enclosures). Flow rate, oscillating tube device = 0.07 l/min. per hole x number of holes; for hand-held nozzle = 10 l/min. Test time, oscillating tube = 10 min.; for hand-held nozzle = 1 min./m2 of enclosure surface area, 5 min. minimum. |

| IP_4 | Protected against splashing water. Same as level 3 but water is sprayed at all angles. | Same as test for IP_3 except spray covers an arc of 180 from vertical. |

| IP_5 | Protected against water jets Water projected at all angles through a 6.3mm nozzle at a flow rate of 12.5 liters/min at a gage pressure of 30kN/m2 for 3 minutes from a distance of 3 meters. | Enclosure is sprayed from all practicable directions with a stream of water at 12.5 l/min. from a 6.3 mm nozzle from a distance of 2.5 to 3 m. Test time = 1 min/m2 of enclosure surface area to be sprayed, 3 min. minimum. |

| IP_6 | Protected against heavy seas. Water projected at all angles through a 12.5mm nozzle at a flow rate of 100 liters/min at a gage pressure of 100kN/m2 for 3 minutes from a distance of 3 meters. | Enclosure is sprayed from all practicable directions with a stream of water at 100 l/min. from a 12.5 mm nozzle from a distance of 2.5 to 3 m. Test time = 1 min/m2 of enclosure surface area to be sprayed, 3 min. minimum. |

| IP_7 | Protected against water immersion. Immersion for 30 minutes at a depth of 1 meter. | Enclosure is immersed in water in its service position for 30 min. Lowest point of enclosures less than 850 mm tall = 1000 mm below surface of water. Highest point of enclosures more than 850 mm tall = 150 mm below surface of water. |

| IP_8 | Protected against water submersion. The equipment is suitable for continuous submersion in water under conditions which are identified by the manufacturer. The position of "X" being left blank indicates that the unit has no special mechanical protection. | Test conditions are subject to agreement between manufacturer and user, but shall be at least as severe as those for IP_7 |

[Top]

If you have any question about Luvo-iDAMiS, please do not hesitate to contact us:

Mr. KV Lim: (6) 012-492 2918 or E-mail to kv@luvotech.com